Changable RF Filter output format

What kinds of output formats do RF filter have?

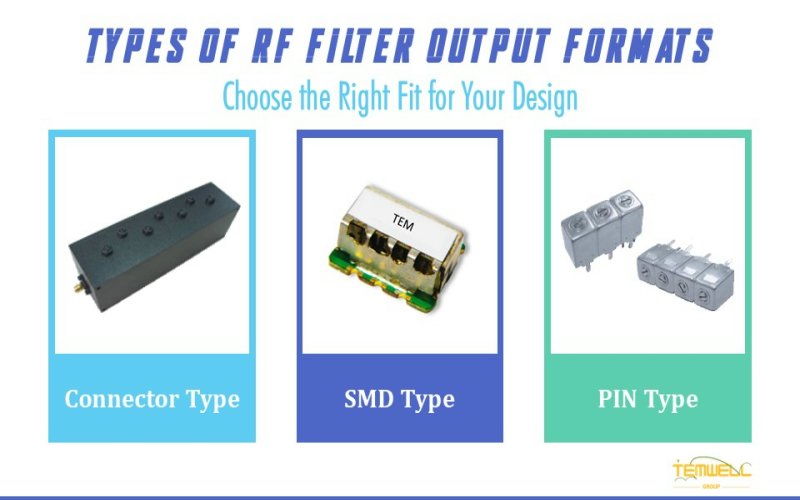

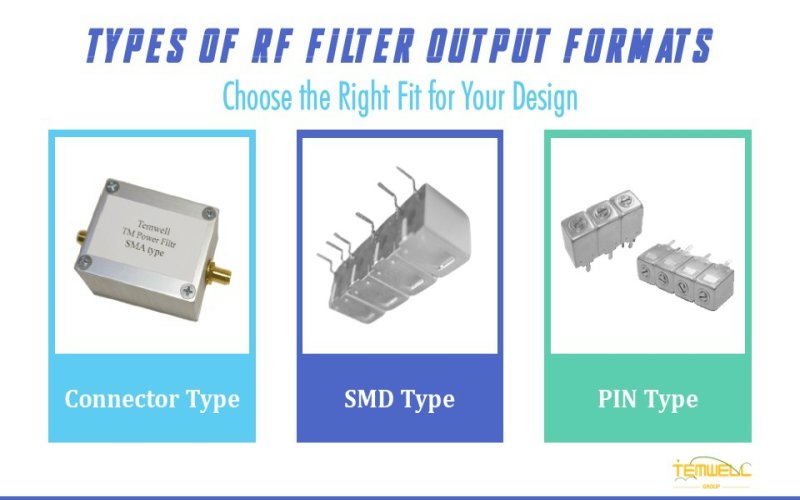

The output format of RF filters directly influences its application scope and installation method. Common output format include Connector Type, SMD (Surface Mount Device) Type, and Pin Type. Different types of RF filters are equipped with the most suitable output configuration depending on its specific application requirement. The most commonly used output formats include the following:

Connector Type:

This format of filter output is equipped with standard RF connectors such as SMA-type, N-type, BNC-type or TNC-type connectors, suitable for high power and low insertion loss applications, and convenient for quick connection to RF equipment. For example, cavity filters often use connector-type output format and are used in base stations, radars, and satellite communications to ensure good mechanical strength and high Q performance. In addition, helical filters can be made in a specially designed way and can also use this format of output to facilitate connection with other RF components.

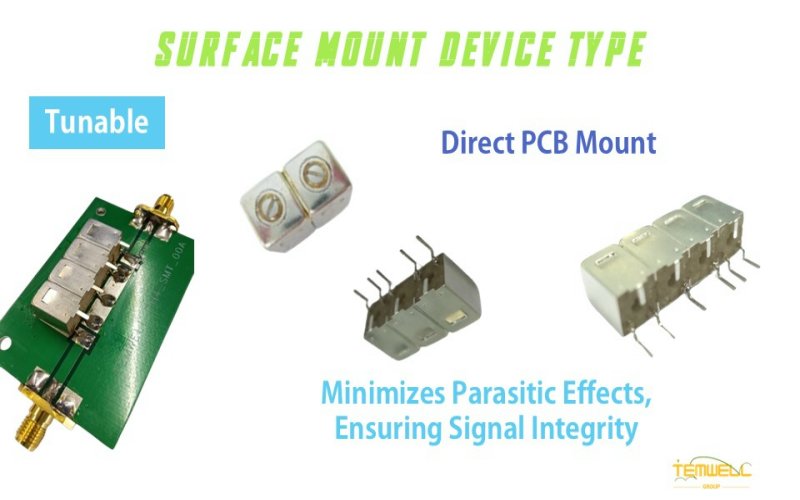

SMD type (Surface Mount Device):

This format of filter output adopts a miniaturized design and can be directly soldered to a PCB board, making it suitable for automated production. This output is directly connected through the PCB pad, which reduces signal loss and parasitic effects and has the advantages of low power consumption, low insertion loss and high integration. For example: Surface acoustic wave filters (SAW Filters) often use SMD output and are used in mobile phones, Wi-Fi modules, and GPS devices. They have the advantages of miniaturization, low power consumption, and high selectivity. There are also dielectric resonator filters (DR filters) that may also use SMD design to meet the miniaturization requirements of modern wireless communication equipment.

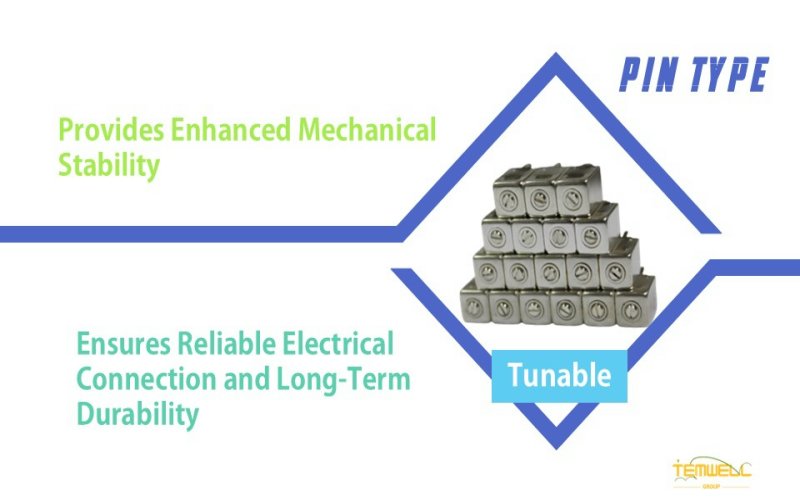

Through hole PIN Type:

PIN filters are usually connected to the circuit board through pins using through-hole soldering. This structure provides higher mechanical stability and is suitable for avionics and industrial applications with good mechanical strength and reliability. For example, helical filters use PIN-type output format and are used in radio equipment, and avionics equipment to ensure stable electrical connections and durability.

Different output formats are suitable for various application scenarios. When designing, the most suitable filter type should be selected according to the frequency range, installation requirements and system requirements to ensure the best signal transmission performance and reliability.

Having multiple filter output format under no change filter performance?!

In radio frequency (RF) design area, it is difficult to find a single filter that can meet the three output formats of connector type, SMD type (Surface Mount Device) and PIN type while maintaining the same filter performance still. This is because different output types will affect impedance matching, insertion loss, mechanical strength and manufacturing process, making them not directly interchangeable.

Cavity Filter, Dielectric Resonance Filter (DR Filter) and Surface Acoustic Wave Filter (SAW Filter) are the three most common RF filters in the RF industry. It is extremely difficult to meet the three output modes of connector type (Connector Type), SMD type (Surface Mount Device) and PIN type (Pin Type) without changing the performance. Impedance matching, parasitic effects, mechanical strength and packaging structure will all change the final output performance of these filters. This means that the output modes of these three filters cannot be directly interchanged.

For cavity filters, the connector type is the most suitable choice because these filters are usually used in high-power, high-Q wireless communication equipment. Using SMA-type or N-type connectors can ensure low loss and mechanical stability. However, if it is changed to a PIN type, although the electrical connection can be achieved by welding, the mechanical structure inside the cavity may need to be redesigned to prevent the Q value from decreasing. The SMD type is almost not feasible because the cavity filter is too large to be directly soldered to the PCB, and changing to SMD format may affect the performance of its resonant cavity, resulting in frequency shift or increased loss.

Dielectric resonant filters mainly use SMD type as the output method, which can be directly soldered to the PCB to reduce parasitic effects and improve automated production efficiency. In applications such as base stations, Wi-Fi and radar, the SMD type package ensures low insertion loss and stable impedance matching. However, unlike other types of filters, dielectric resonator filters are difficult to convert to PIN type because their internal structure is highly dependent on the resonance characteristics of the dielectric material. Soldering through the PIN method may change the electric field distribution, thereby affecting the resonant frequency and Q value, resulting in performance degradation. If the output is through a connector, parasitic effects will often be introduced, affecting the frequency response of the filter. Therefore, SMD type is the mainstream output mode of dielectric resonant filter (DR Filter).

The output options for surface acoustic wave filters (SAW Filter) are more limited. The SMD type is the standard design of SAW filters because these filters are often used in mobile phones, Wi-Fi, GPS, and other small consumer electronic devices, and the SMD package ensures good surface mount characteristics and low insertion loss. However, if it is to be changed to a PIN type, the package needs to be modified, such as adding pins or soldering through vias, but this may affect the PCB design and even the acoustic wave transmission characteristics of the SAW filter. The connector type is almost not feasible because SAW filters are mainly used in low-power applications, and the use of connectors will add additional parasitic effects and volume, which is completely inconsistent with the requirements of miniaturization.

As above, the three mainstream filters are cavity filters, dielectric resonator filters (DR filters) and surface acoustic wave filters (SAW filters). The working mechanisms of filters are different, and it is difficult to meet the three output modes at the same time without changing their electrical and mechanical properties. When designing, engineers usually choose a suitable output method based on actual application requirements, rather than trying to make a single filter adapt to all output types, because doing so may affect the overall performance of the filter and even lead to design compromises.

Overall, due to the different operational mechanisms of Cavity Filters, Dielectric Resonator Filters (DR Filters), and Surface Acoustic Wave Filters (SAW Filters) , it is difficult to simultaneously satisfy all three output formats without altering their electrical and mechanical performance. RF Engineers typically choose the most suitable output type based on the specific application requirements, rather than attempting to make a single filter adaptable to all output types, as doing so could impact the filter's overall performance and lead to inappropriate design result.

Temwell Customized Service-Output format

With over 27 years of experience, Temwell provides professional Helical Filter customization services. While maintaining the same product performance, it supports three different output methods: Connector Type, SMD Type (Surface Mount Device) and PIN Type, allowing customers to choose the most suitable solution according to their application requirements.

Through precise electrical design and mechanical structure adjustment, Temwell ensures that each output method can maintain the same RF filter characteristics, including center frequency, bandwidth, insertion loss, Rejection value and impedance matching. The connector type is suitable for modular systems, such as communication equipment and test instruments, to ensure plug-and-play convenience; the SMD type is suitable for highly integrated PCB design, which can simplify the assembly process and improve production efficiency; and the PIN type provides a stable welding method, suitable for military, aerospace and high-reliability applications.

Temwell's customization service not only provides flexible output mode changes, but also ensures that the product maintains consistent high performance across different packages. No matter how the customer's application requirements change, Temwell can provide the most optimized Helical Filter solution to enhance the flexibility of product design and market competitiveness.

If your team has any needs for RF BPF, please feel free to contact us and get free consultation services so that we can provide you with the best solution.

Subscribe to us on Facebook for the latest product news.